Yet unpublished results

« Thermodynamic assessment of the Ti + C → TiC reaction in presence of nickel and a moderator.»

Hafida Boutefnouchet, Dominique Vrel,

International Journal of Self-propagating High-tempererature Synthesis, accepted.

We present thermodynamic calculations concerning the adiabatic temperatures of the SHS reaction producing TiC in presence of nickel, either metallic or resulting from the aluminothermitic reduction of nickel monoxide, and a reaction moderator, alumina or magnesia. In addition, some emphasis is put on the amounts of the various liquid phases which may have a key role on the densification of the resulting products.

« Textured ZnO Thin Films by Sol-Gel Process: Synthesis and Characterizations.»

L. Znaidi, T. Chauveau, A. Tallaire, F. Liu, M. Rahmani, V. Bockelee, D. Vrel, P. Doppelt,

Thin Solid Films, published on line.

Textured zinc oxide thin films were synthesized by the sol-gel process using zinc acetate dihydrate, ethanol and monoethanolamine as precursor, solvent and stabilizer, respectively. The structural, morphological, and luminescence properties of the thin films have been investigated as a function of precursor concentration (0.25, 0.50 and 0.75 mol.L-1) using X-Ray Diffraction, Quantitative Texture Analysis, Scanning Electronic Microscopy, Atomic Force Microscopy and Cathodoluminescence. The morphology of the films and their crystallographic orientation has been found to be strongly influenced by the precursor concentration. For the lowest concentration, the strongest <00.2> texture and the lowest roughness are obtained. At higher concentrations, secondary <50.2> and <10.3> textures are also observed.

2016

« Synthesis of Nanometric Refractory Alloys Powders in the Mo-Nb-W System.»

Vasuki Kentheswaran, Sarah Dine, Dominique Vrel, Jean-Philippe Couzinié, Guy Dirras,

Journal of Alloys and Compounds, 679 (2016) 80-87.

Nanometric powders of stoichiometric compositions in the Mo-Nb, Mo-W, Nb-W binary systems and in the Mo-Nb-W ternary system were produced by highly exothermic reactions using Mechanically Induced Chemical Reaction (MICR), Self-propagating High-temperature Synthesis (SHS) and Mechanically Activated Self-propagating High-temperature Synthesis (MASHS), through the reduction of their oxides by magnesium, with sodium chloride used as a reaction moderator. Results demonstrate the possibility to obtain high purity nanostructured products in the 20-150 nm range, with an average equivalent diameter, from specific surface measurements, of 44 nm. However, in Nb containing samples, the main BCC phase always comes with one or more secondary phases, for which further developments are necessary in order either to avoid its formation or to find a way to eliminate it..

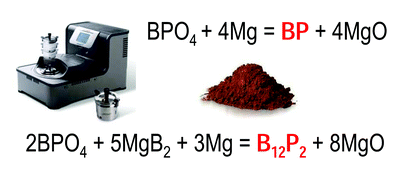

« Ultra-Fast Mechanochemical Synthesis of Boron Phosphides, BP and B12P2.»

Vladimir A. Mukhanov, Dominique Vrel, Petr S. Sokolov, Yann Le Godec, Vladimir L. Solozhenko,

Dalton Transactions, (2016) (yet only published online).

Here we propose a new approach to the synthesis of single-phase boron phosphides (BP and B12P2) by mechanochemical reactions between boron phosphate and magnesium/magnesium diboride in the presence of an inert diluent (sodium chloride). The proposed method is characterized by the simplicity of implementation, high efficiency, low cost of the product, and good perspectives for large-scale production.

2015

« Synthesis of tungsten nanopowders: comparison of milling, SHS, MASHS and Milling-Induced Chemical Processes.»

S. Dine, S. Aïd, K. Ouaras, V. Malard, M. Odorico, N. Herlin-Boime, A. Habert, A. Gerbil-Margueron, C. Grisolia, J. Chêne, G. Pieters, B. Rousseau, D. Vrel,

Advanced Powder Technology, 26 (2015) 1300-1305.

Synthesis of tungsten nanopowders was studied using milling of micrometric tungsten, then using the WO3-Mg thermitic reaction, using SHS (Self-propagating High-temperature Synthesis), milling induced chemical reaction (MICR), and MASHS (Mechanically Activated SHS). Reactions are studied by measuring temperature and pressure inside the milling jar (MICR), or by analyzing the temperature profile along the sample during the reaction propagation by infrared thermography (SHS, MASHS). After reaction, samples were analyzed by AFM or SEM, by XRD, and BET. MASHS seems to possess optimum conditions with a pre-milling before SHS of 10 minutes, which yielded the highest tungsten purity, together with a large grain size corresponding to our aim.

« Tungsten dust nanoparticles generation from blistering bursts under hydrogen environment in microwave ECR discharge.»

K. Ouaras, K. Hassouni, L. Colina Delacqua, G. Lombardi, D. Vrel, X. Bonnin,

Journal of Nuclear Materials, 466 (2015) 65-68.

Blistering burst induced tungsten dust nanoparticles were observed for the first time when a tungsten sample is submitted to a hydrogen low-temperature discharge under low flux and low incident energy values (20, 120 and 220 eV) at a surface temperature of 500 K. Tungsten nanoparticles (~ 50nm) were organized in 2D domains with diameter that is well correlated to the blister volume losses by burst. These observations suggest that dust nanoparticles were generated from blistering burst.

« Tritium absorption and desorption in ITER relevant materials : comparative study of tungsten dust and massive samples.»

C. Grisolia, E. Hodille, J. Chêne, S. Garcia-Argote, G. Pieters, A. El-Kharbachi, L. Marchetti, F. Martin, F. Miserque, D. Vrel, M. Redolfi, V. Malard, G. Dinescu, T. Acsente, F. Gensdarmes, S. Peillon, B. Pegourié and B. Rousseau,

Journal of Nuclear Materials, 463 (2015), 885-888.

Tritium adsorption and desorption from well characterized tungsten dust are presented. The dust used are of different types prepared by planetary milling and by aggregation technique in plasma. For the milled powder, the surface specific area (SSA) is 15.5 m2/g. The particles are poly-disperse with a maximum size of 200 nm for the milled powder and 100 nm for the aggregation one. Prior to tritiation the particles are carefully de-oxidized. Both samples are experiencing a high tritium inventory from 5 GBq/g to 35 GBq/g. From comparison with massive samples and considering that tritium inventory increases with SSA, it is shown that surface effects are predominant in the tritium trapping process. Extrapolation to the ITER environment is undertaken with the help of a Macroscopic Rate Equation model. It is shown that, during the life time of ITER, these particles can exceed rapidly 1 GBq/g.

« The Formation Of (Al8Fe2Si, Al13Fe4) Phases From Al-Fe-Si System By TE Mode.»

Boulouma, A.; Drici, A.; Benaldjia, A.; Guerioune, M.; Vrel, D,

AIP Conference Proceedings, 1653 (2015), 020023.

This work prepared Al8Fe2Si, Al13Fe4 mixed sample by ball milling and thermal explosion techniques applying Al, Fe and Si powders as precursors. Thermal combustion of powder mixes of composition 24,37 Al+ 50,36 Fe + 25,27 Si in mass reveals production of several binary and ternary intermetallic phases such: A113Fe4 and Al8Fe2Si.. Synthesis conditions were optimized to fabricate these phases having many potential applications.

2014

« Experimental studies of the interactions between a hydrogen plasma and a carbon or tungsten wall.»

K Ouaras, L Colina Delacqua, C Quirós, G Lombardi, M Redolfi, D Vrel, K Hassouni and X Bonnin,

Journal of Physics : Conference Series, 591 (2014), conference 1, 17422-17428.

We present work done at LSPM (Laboratory of Sciences of Processes and Material Sciences), using the CASIMIR ECR plasma reactor device, aimed at answering questions about hydrogen isotope fuel retention and dust production in the context of the plasma-facing components (PFCs) of the International Thermonuclear Experimental Reactor (ITER). The plasma is characterized by means of optical spectroscopy, mass spectrometry and electrostatic probe; furthermore the dust density and size distribution will be measured by a laser diagnostic system. We present some early results obtained from hydrogen plasma exposure of pure tungsten samples, as well as samples of ITER-relevant tungsten-rich powders, produced inhouse by the ball-milling technique, which are likely to be a by-product of material erosion and migration during tokamak operation. In particular, we have performed measurements of the specific surface area of these powders as a proxy to their capacity to absorb hydrogen.

« Synthesis and Hydrogen Plasma Interaction of Model Mixed Materials for Fusion.»

K. Ouaras, S. Dine, D. Vrel, X. Bonnin, M. Redofi, G. Lombardi, K. Hassouni,

International Journal of Hydrogen Energy, 39 (2014), 30, 17422-17428.

Samples of mixed materials relevant to fusion (W/C/Mg, where Mg is a chemical stand-in for Be) have been synthesized by planetary ball milling. We explore here W-rich compounds, and investigate their structural and physico-chemical properties, both before and after hydrogen plasma exposure. After presenting the synthesis method experimental results are detailed: clear differences between incorporation of magnesium and/or carbon into a tungsten matrix are observed, as reflected in the specific surface area of the samples and their lattice parameters. Indeed, specific surface area decreases with increasing Mg content but increases with C content. The same trend is seen for the lattice parameter. A particular effect seen after hydrogen plasma exposure is attributed to the presence of magnesium which may also occur in the presence of beryllium.

« NiAl Intermetallics Dispersion-Strengthened with Silica, Alumina, and Mullite : Synthesis and Characterization.»

D. Boyarchenko, A. E. Sytschev, S. G. Vadchenko, I. D. Kovalev, A. S. Shchukin, and D. Vrel,

International Journal of Self-Propagating High-Temperature Synthesis, 23 (2014), 2, 83-88.

Ni-Al intermetallics dispersion-strengthened with silica, alumina, and mullite were prepared by SHS under load and characterized by XRD and SEM/EDS. The observed formation of a transition zone between the embedded mullite particles and NiAl matrix in combustion-synthesized NiAl-mullite composites can be expected to improve the service parameters of thus synthesized material.

« Synthesis of Nanocrystalline NiAl By Mechanically Activated Self-Propagating High-Temperature Synthesis And Mechanically Activated Annealing Process.»

S. Arroussi, M. Ali Rachedi, A. Benaldjia, M. Andasmas, M. Guerioune, D. Vrel,

The European Physical Journal Applied Physics, 64 (2013), 3, 30401.

The mechanically activated self-propagating high-temperature synthesis (MASHS) technique and the mechanically activated annealing process (M2AP) were used to produce NiAl intermetallic compound. Rietveld analysis of X-ray diffraction data was used to characterize the mechanically activated powders, MASHS and M2AP end-products. Two-phase (B2+L12) nickel aluminide intermetallic compounds were synthesized by the mechanically activated volume combustion synthesis (MASHS). A single phase B2 NiAl was formed when mechanically activated annealing process (M2AP) was performed. Starting from a mixture of elemental pure powders, both M2AP and MASHS milling processes lead to nanostructured powders. Structural analysis deduced from the Rietveld refinement of X-ray diffraction patterns of NiAl compounds synthesized by SHS after a milling of 6 h show the formation of β-NiAl phase with a cell parameter a = (0.2885 ± 1.2618 × 10-4) nm. The average crystallite size is D = (44.6421 ± 2.4263) nm and the microstrains values are close to those of metallic alloys ε = (0.2142 ± 1.6186 × 10-2)%. Finally, scanning electron microscopy (SEM) was carried out to characterize the microstructure of end-products.

« Self-Propagating High-Temperature Synthesis of Boron Subphosphide, B12P2.»

V. A. Mukhanov, P. S. Sokolov, O. Brinza, D. Vrel, and V. L. Solozhenko,

Journal of Superhard Materials, 36 (2014), 1, 18-22 (Original Russian Text, Sverkhtverdye Materialy, 2014, 36, 1, 27-32).

Two new methods to produce nanopowders of B12P2 boron subphosphide by self-propagating high-temperature synthesis have been proposed. Bulk polycrystalline B12P2 with microhardness of HV = 35(3) GPa and stability in air up to 1300 K has been prepared by sintering these powders at 5.2 GPa and 2500 K.

« Tritium Absorption/Desorption in Iter-Like Tungsten Particles.»

A. El Kharbachi, J. Chêne, S. Garcia-Argote, L. Marchetti, F. Martin, F. Miserque, D. Vrel, M. Redolfi, V. Malard, C. Grisolia, B. Rousseau,

International Journal of Hydrogen Energy, 39 (2014), 10526-10536.

Tritium retention in plasma facing materials such as tungsten is a major concern for future fusion reactors. During ITER operating mode, the reactor could generate tritiated tungsten dust-like particles which need to be characterized in terms of amount of trapped tritium, tritium source and radiotoxicity. This study is focused on the preparation of representative ITER like tungsten particles and on a comparative analysis of tritium absorption/desorption kinetics in these particles and in massive samples. An original gas phase thermal charging procedure was used successfully for tritium incorporation in tungsten powders and massive samples. Much larger tritium amounts are incorporated in W particles than in massive samples indicating important surface effects on tritium absorption, desorption and trapping in W. Tritium desorption from particles occured at different temperatures related with different interactions on the particles surface and in the bulk ; the tritium behavior in massive samples was also shown to depend on the metal microstructure. According to these experimental results tritium absorption/desorption in W particles may have important implications on tritium management in ITER reactor.

2013

« Low optical loss nano-structured TiO2 planar waveguides by sol-gel route for photonic crystal applications.»

T. Touam, L. Znaidi, D. Vrel, I. Hadjoub, I. N. Kuznetsova, O. Brinza, A. Fischer, A. Boudrioua,

Optical and Quantum Electronics, (2013).

Nano-structured TiO2 planar waveguides were prepared by sol-gel route: titanium tetraisopropoxide was dissolved in isopropanol, and then hydrolyzed by adding a water/isopropanol mixture with a controlled hydrolysis ratio. The resulting sol was deposited by "dip-coating" on a glass substrate with a controlled withdrawal speed. The obtained films were annealed for 2 h at 350 and 500 °C, respectively. The structural and morphological properties of the synthesized films were analyzed by X-ray diffraction, scanning electron microscopy, and atomic force microscopy. Optical properties such as refractive index, thickness, number of propagating modes, and attenuation coefficient were measured at 632.8 nm by m-lines spectroscopy as a function of the elaboration parameters. The films exhibit diffraction pattern consistent with an anatase phase and the TiO2 planar waveguides are multimodes and demonstrate propagation losses as low as 0.3 dB/cm.

« AZO Thin Films by Sol-Gel Process for Integrated Optics.»

Lamia Znaidi, Tahar Touam, Dominique Vrel, Nacer Souded, Sana Ben Yahia, Ovidiu Brinza, Alexis Fischer and Azzedine Boudrioua,

Coatings, 3, 3, 126-139 (2013).

Undoped and aluminum-doped zinc oxide (AZO) thin films are prepared by the sol-gel process. Zinc acetate dihydrate, ethanol, and monoethanolamine are used as precursor, solvent, and stabilizer, respectively. In the case of AZO, aluminum nitrate nonahydrate is added to the precursor solution with an atomic percentage equal to 1 and 2 at.% Al. The multi thin layers are deposited by spin-coating onto glass substrates, and are transformed into ZnO upon annealing at 550 °C. Films display a strong preferential orientation, with high values for the Texture Coefficients (TC) of the (002) direction (TC(002) = 3). The structural, morphological, and optical properties of the thin films as a function of aluminum content have been investigated using X-Ray Diffraction (XRD), Atomic Force Microscopy (AFM), and Scanning Electronic Microscopy (SEM). Waveguiding properties of the thin films have been also studied using m-lines spectroscopy. The results indicate that the films are monomodes at 632.8 nm with optical propagation optical losses estimated around 1.6 decibel per cm (dB/cm).

« Low loss sol-gel TiO2 thin films for waveguiding applications.»

T. Touam, L. Znaidi, D. Vrel, I. N. Kuznetsova, O. Brinza, A. Fischer, A. Boudrioua,

Coatings, 3, 1, 49-58 (2013).

TiO2 thin films were synthesized by sol-gel process: titanium tetraisopropoxide (TTIP) was dissolved in isopropanol, and then hydrolyzed by adding a water/isopropanol mixture with a controlled hydrolysis ratio. The as prepared sol was deposited by "dip-coating" on a glass substrate with a controlled withdrawal speed. The obtained films were annealed at 350 and 500°C (2 h). The morphological and optical properties of the prepared films were analyzed by X-ray Diffraction (XRD), Scanning Electron Microscopy (SEM), and Atomic Force Microscopy (AFM). The optical waveguiding properties of TiO2 films were investigated for both annealing temperature using m-lines spectroscopy. The refractive indices and the film thickness were determined from the measured effective indices. The results show that our fabricated planar waveguides are multimodes and demonstrate low propagation losses of 0.44 and 0.80 dB/cm for annealing temperature 350 and 500°C, respectively.

« Combustion Synthesis in the Ni-Al-W System: Some structural Features.»

A. E. Sytschev, D. Vrel, Yu. R. Kolobov, D. Yu. Kovalev, E. V. Golosov, A. S. Shchukin, and S. G. Vadchenko,

International Journal of Self-Propagating High-Temperature Synthesis, 22, 2 , 110-113 (2013) .

Explored was the combustion synthesis in the Ni-Al-W system with special emphasis on structural features of the process. Using SHS in the 1500-1700°C temperature range, we observed diffusion-induced processes at the interface between synthesized NiAl and W particles, resulting in the formation of W2Ni and W-Ni intermetallics.

« Deposition of Ni-Al Coatings onto Copper by Mechanical/Heat Treatment.»

A.E. Sytschev, S. M. Busurin, D. Yu. Kovalev, D.Vrel, O. D. Boyarchenko, S.G. Vadchenko, N. V. Sachkova,

International Journal of Self-Propagating High-Temperature Synthesis, 22, 2, 103-109 (2013) .

The transition layer formed upon deposition of Ni-Al coatings onto the surface of Cu substrates by using the technique of mechanical treatment followed by annealing was found to contain α-(Cu,Ni) solid solution, Cu9Al4, Ni3Al, NiAl, Ni2Al3, and NiAl3. The mechanism for formation of protective coating in the Ni-Al-Cu system was discussed.

« Combustion Synthesis: Novel Routes to Novel Molecular Nanomaterials.»

B. Bendjemil, A. Lankar, A. Benaldjia, J. Messadi and Dominique Vrel,

International Journal of Self-Propagating High-Temperature Synthesis, 22, 2, 119-124 (2013) .

Combustion synthesis in an electrothermal explosion mode was used with the aim to synthesize 1D carbon nanostructures, by magnesium reduction of various carbonates (Li2CO3, Na2CO3, CaCO3, FeCO3, (NH4)2CO3), either in argon or in air, at ambient pressure (0.1 MPa) or at 1 MPa. In the same time, several possible catalysts were tried, such as Fe, Co, Ni, Pd, Nd, Ta, Ti, Nb, W, and NiO powders. Through the presence of MgO in the product, the deep reduction of carbonates is shown. In order to produce fibrous products, the Na2CO3 system proved to be the most promising system. On the other hand, carbon encapsulated metal nanoparticles were obtained in our samples, opening the process to new possible bio-applications..

« Crystallisation of immobilised anatase TiO2 nanoparticles.»

O. Khatim, M. Amamra, K. Chhor, T. Bell, D. Novikov, D. Vrel, A. Kanaev,

Chemical Physics Letters, 558, 12 February 2013, 53-56 (2013) .

Kinetics of the amorphous-anatase phase transition in single immobilized 5-nm TiO2nanoparticles has been studied at temperatures between 400 and 1000°C at the DORIS-III synchrotron source of Hasylab. The measurements indicate the anatase phase appearance at temperatures above 500°C. No formation of rutile phase was observed. The transformation kinetics for each fixed temperature is rapid and completes within 5 min. The crystalline mass progressively increases with temperature and the full transformation into anatase polymorph is achieved above 800°C. The results suggest higher surface energy of the anatase phase compared to amorphous one, which delays the crystallization process.

« SHS welding by thermal explosion: Ti-Ti and Ti-NiAl joints.»

A. E. Sytschev, S. G. Vadchenko, O. D. Boyarchenko, D. Vrel, N. V. Sachkova ,

International Journal of Self-Propagating High-Temperature Synthesis, 22, 2, 99-102 (2013) .

Ti-Ti and Ti-NiAl joints were obtained by thermal explosion in the Ti-Ni-Al system. The bulk Ti samples used as a substrate were preliminary coated with mechanically activated Ni-Al powders by the method of mechanical cold working. The Ti-Ti joints were found to have the NixAlyTiz composition and lower porosity compared to that of Ti-NiAl joints.

« Load-Assisted SHS Joining of NiAl to Ni.»

A. E. Sytschev, D. Vrel, O. D. Boyarchenko, S. G. Vadchenko, N. V. Sachkova,

International Journal of Self-Propagating High-Temperature Synthesis, 22, 1, 52-55 (2013) .

The joining of NiAl to Ni substrates was carried out through load-assisted SHS reaction. The process of bonding between liquid reaction products and Ni substrate was studied. A transition layer at the NiAl/Ni interface was found to form mainly due to the diffusion of Al. The components of Ni-rich phases were found to undergo diffusion into the reaction products. Microstructural observations showed the formation of excellent bonding at the NiAl/Ni interface.

« Planetary Ball Milling: Geometry-Based Considerations.»

D. Vrel,

Acta Materialia Sorbonica 1, 1, 1-10 (2013) .

Using simple calculations and a spreadsheet based implementation, velocities and movement of the balls present in a jar are computed. From these calculations, considerations regarding the wear and tear of the milling media, efficiency of the milling and the nature of the shocks, i.e. frontal shocks or not, are deduced.

« SHS of graded Ti-Al-C ceramics: Composition of transition layers.»

A. E. Sytschev, D. Vrel, O. D. Boyarchenko, S. G. Vadchenko, D. Yu. Kovalev, N. V. Sachkova,

International Journal of Self-Propagating High-Temperature Synthesis, 21, 4, 231-255 (2013) .

Due to large reaction rates, high temperatures reached during the reaction, and rapid cooling that may reduce the heat-affected zone, SHS seems to be a good candidate for welding applications. The potential of this process was explored for titanium-rich compounds, with the aim of welding dissimilar materials.

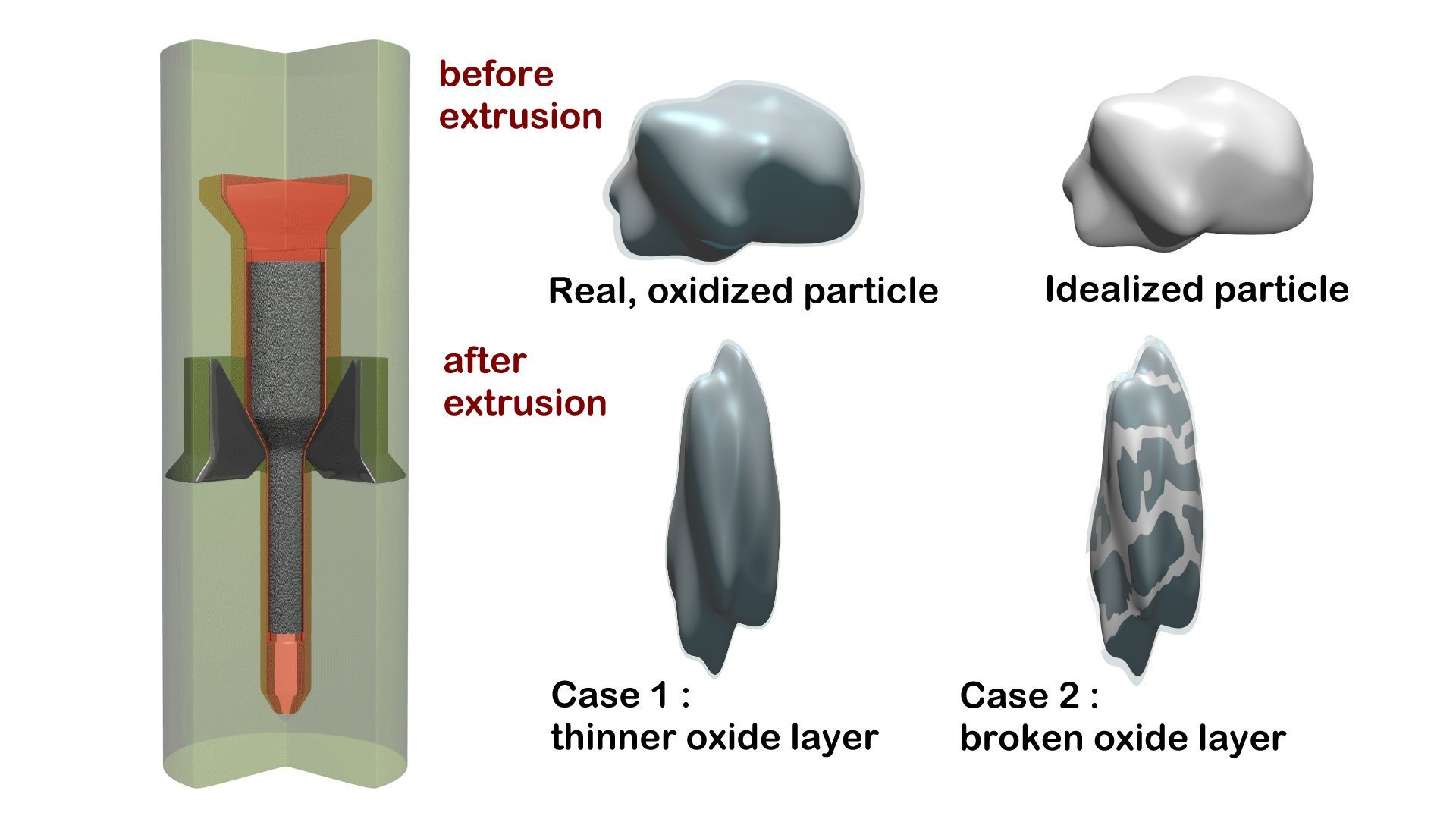

« Synthesis of NiAl intermetallics from cold-extruded samples.»

M. Andasmas, T. Chauveau, N. Fagnon, D. Vrel,

Intermetallics 32, 137-144 (2013).

In a previous study, we described the phenomenological densification behavior of Ni-Al mixtures, up to a pressure of 100MPa. The following use of Differential Hydrostatic Extrusion, forcing on the sample non-isotropic plastic deformations allowed a final densification of 98.4% on the stoichiometric mixture. Due to this plastic deformation, the contact area between Ni and Al was improved, with the possible destruction of intermediate oxide layers. Following this idea, the reactivity of these samples was studied under argon at 450°C, 550°C and 800°C. The formation of intermetallics was observed from 450°C by solid state diffusion, while at 550°C, the mechanical activation provided by differential hydrostatic extrusion allowed the sample to undergo Thermal Explosion. Using a low heating rate, this phenomenon could be avoided, and we were able to recover high density NiAl with a strong preferred orientation by a heat treatment at 800°C.

2012

« Peculiar Features of Interaction of Intermetallic Compounds Based on Ti-Al, Ni-Al with Ti and Ni Metallic Substrates in the Mode of Self-Propagating High-Temperature Synthesis.»

A. E. Sychev, S. G. Vadchenko, O. D. Boyarchenko, D. Vrel, N. V. Sachkova,

Inorganic Materials: Applied Research, 2012, 3, 5, 376-380.

Self-propagating high-temperature synthesis (SHS) is applied for production of titanium and nickel aluminides with various operating properties, which is important for deformation of items in the SHS mode and application of coatings on intermetallic and metallic substrates (for instance, Ti, Ni, Al, and others). The possibilities of application of intermetallic coatings and joining (welding) of such materials in the SHS mode are studied.

« Особенности взаимодействия интерметаллиндов на основе Ti-Al, Ni-Al с металлическими родложками Ti и Ni в режиме саморасрространяющегося высокотемрератuрного (SHS Joining of Ti-Al and Ni-Al Intermetallics to Mechanoactivated Ti and Ni Substrates).»

А. Е. Сычев, С. Г. Вадченко, О. Д. Боярченко, D. Vrel, Н. В. Сачкова,

Персрективиые Материалы 2012, 2, 15-20.

« In-Situ Characterization of Dust Mobilized by Laser Cleaning Methods and Loss of Vacuum Accident.»

F.R.A. Onofri, S. Barbosa, M. Wozniak, J. Mroczka, D. Vrel, C. Grisolia,

Fusion Science and Technology, 62, (2012), 39-45.

We investigate the ability of light extinction spectrometry (LES) to characterize, at long distances, the size distribution and concentration of dust mobilized by laser cleaning methods (ITER wall detritiation and characterization of deposition layers) or by experiments dealing with a loss-of-vacuum accident. Potentially harmful effects induced by wall proximity, plasma plume broadband emission, and associated shock waves are shown to have a negligible influence on LES measurements, which demonstrates the interest in this optical technique for the aforementioned studies. However, our experimental results, based on aerosols of silica and tungsten powder aggregates, show that the present setup allows the characterization of dust volume fractions of less than ≈ 1-10 ppb for a probing length of 1 m (or by extrapolation ≈ 0.1-1 ppb for a probing length of 10 m).

« Coprecipitation on slurry to prepare drug-silica polymer formulations by compressed antisolvent.»

P. Subra-Paternault, D. Vrel, C. Roy,

Journal of Supercritical Fluids, 63, (2012), 69-80.

This work proposes for the first time a coprecipitation-on-slurry method using CO2 as antisolvent to prepare formulations of a poorly water-soluble drug (tolbutamide) with micrometric silica (60 and 5 μm) and biopolymers. Mixtures were processed from acetone using the batch gas antisolvent method. Polyethylene glycols and Eudragits were selected as polymers capable to modify the drug dissolution behavior. Morphology, size distribution, crystal lattice and dissolution kinetic were characterized. Products were recovered as powders providing a polymer/silica ratio of 50/50, with coarser grains in Eudragits powders compared to PEG's. The size distribution evidenced populations between 10 and 100 µm that were not obtained when TBM was single processed, together with larger agglomerates. In terms of precipitation mechanism, the drug has grown almost unaffected by the presence of silica and polymer in the liquor except for a smaller size, since neither the morphology nor the crystal lattice was significantly changed. The products exhibited substantially different rates of dissolution in accordance with the polymer function: the water-soluble PEGs improved the dissolution rate whereas the water-insoluble Eudragit sustained notably the drug release..

« Superconducting NbTi by Combustion Synthesis.»

B. Benjemil, A. Hafs, A. Benaldjia, D. Vrel,

International Journal of Self-propagating High-temperature Synthesis, 21, (2012), Issue 2, Pages 117-123.

Electrothermal explosion (ETE) initiated by the heavy current (500 A) allowed to pass through mechanically activated Nb-Ti mixtures for 180 s yielded the products containing a mixture of β-NbTi and α-NbTi preliminary characterized by XRD, FESEM, EDX, and AES.

« Combustion Synthesis: Novel Routes to Novel Molecular Nanomaterials.»

B. Benjemil, A. Lankar, A. Benaldjia, D. Vrel,

International Journal of Self-propagating High-temperature Synthesis, 21, (2012), Issue 3, to be published.

« Characteristics of nanostructured ZnO layers deposited in Spray plasma device.»

Kamal Baba, Mehrdad Nikravech, Dominique Vrel, Andrei Kanaev, Luc Museur, Mohamed Chemini,

Journal of Nanoscience and Nanotechnology, 12, (2012) Pages 1-5.

ZnO and Al doped ZnO thin film have been deposited on glass substrate by "spray plasma" process using an aqueous solution of Zn(NO3)2. XRD patterns revealed polycrystalline character with the typical hexagonal würtzite structure. The preferential c-axis orientation of crystallites depends highly on the operating conditions. Willamson-Hall method and AFM photographs showed a size of crystallites ranging between 20 and 80 nm and a roughness between 6 and 50 nm. Films exhibit a transmittance between 65 and 90% in the visible region. XPS revealed that the stoichiometry of deposited ZnO is Zn/O = 0.93. Fluorescence spectroscopy showed the presence of two bands at 360 nm (UV) and at 410 nm (Blue). The UV band can be attributed to exiton emission. Another important result concerns the non-existence of a "green" band at 500 nm. .

« ZnO thin films synthesized by sol-gel process for photonic applications.»

L. Znaidi, T. Touam, D. Vrel, N. Souded, S. Ben Yahia, O. Brinza, A. Fischer, A. Boudrioua,

Acta Physica Polonica A, 121 (2012), 1, 165-168.

Undoped and aluminum-doped ZnO thin films are prepared by the sol-gel process. Zinc acetate dihydrate, ethanol and monoethanolamine are used as precursor, solvent and stabilizer, respectively. In the case of Al-doped ZnO, aluminum nitrate nonahydrate is added to the precursor solution with an atomic percentage equal to 1 or 2 at.% Al. The multi thin layers are prepared by spin-coating onto glass substrates, and are transformed into ZnO upon annealing at 550°C. Films with preferential orientation along the c-axis are successfully obtained. The structural, morphological, and optical properties of the thin films as a function of aluminum content have been investigated for different elaboration parameters (e.g. layer number) using X-ray diffraction, atomic force microscopy, scanning electronic microscopy. Waveguiding properties of the thin films have been also studied using m-lines spectroscopy. The results indicate that our films are monomodes at 632.8 nm with propagation optical loss estimated around 1.6 dB/cm..

« Self-propagating High-Temperature Synthesis mechanisms within the Ti-C-Ni system: A Time Resolved X-Ray Diffraction study.»

H. Boutefnouchet, C. Curfs, A. Triki, A. Boutefnouchet, D. Vrel,

Powder Technology, 217, 443-450.

An experimental study on direct formation of TiC-Ni composite by Self-propagating High-temperature Synthesis (SHS) was conducted using a Ti-C-xNi systems (x = 5, 10, 15 wt%). Composites of this kind are known to exhibit interesting structural and mechanical properties (high strength in shear and compression, high service temperature capabilities), thanks to the combination of metallic (ductility and toughness) and ceramic (high strength, modulus and hardness) properties. X-ray Powder diffraction (XRPD) experiments performed on the combustion-synthesized products have shown that the main products were always TiC and Ni acting as a binding phase, but that the reaction might be incomplete in some cases, and the formation of a small amount of Ni-Ti compounds and metastable Ni3C was observed. To understand the chemical pathway, a time resolved X-ray diffraction experiment (TRXRD) using synchrotron radiation (ESRF ID-11, Materials Science Beamline) was performed to follow the reaction in situ on a time scale of ~ 35 ms. This analysis showed that TiC was the first phase to form through solid-state diffusion of C into β-Ti, followed by Ti-Ni melt and finally the simultaneous appearance of metallic Ni and Ni3Ti, suggesting an eutectic reaction during the cooling stage. Using Rietveld refinement, some critical temperatures were estimated via thermal expansion/contraction of the lattice parameter of TiC during the combustion reaction.

2011

« Waveguiding Properties of NanoStructured TiO2 Thin Films Synthesized by Sol-Gel Process.»

L. Znaidi, T. Touam, D. Vrel, I.N. Kunetsova, A. Fischer and A. Boudrioua

AIP Conf. Proc. 1400, 268 (2011)

TiO2 thin films were synthesized by sol-gel process: titanium tetraisopropoxide (TTIP) was dissolved in isopropanol, and then hydrolyzed by adding a water/isopropanol mixture with a controlled hydrolysis ratio. The as prepared sol was deposited by "dip-coating" on a glass substrate with a controlled withdrawal speed. The obtained films were annealed at 350 and 500°C (2 h). The morphological and optical properties of the prepared films were analyzed by X-ray Diffraction (XRD), Scanning Electron Microscopy (SEM), and Atomic Force Microscopy (AFM).The optical waveguiding properties of TiO2 films were investigated for both annealing temperature using m-lines spectroscopy. The refractive indices and the film thickness were determined from the measured effective indices. The results show that our fabricated planar waveguides are multimodes and demonstrate low propagation losses of 0.9 dB/cm.

« SHS Joining of Intermetallics with Metallic Substrates.»

A. E. Sytschev, S. G. Vadchenko, O. D. Boyarchenko, D. Vrel, and N. N. Sachkova

International Journal of Self-propagating High-temperature Synthesis, 20, 3, 183-188.

SHS-produced Ti-Al and Ni-Al intermetallics have been successfully joined to mechanically activated Ti and Ni substrates by SHS reactions under moderate pressure.

« Effect of CO2-antisolvent techniques on size distribution and crystal lattice of theophylline.»

Christelle Roy, Dominique Vrel, Arlette Vega-Gonzalez, Patrick Jestin, Serge Laugier, Pascale Subra-Paternault

The Journal of Supercritical Fluids, 57, 3, 267-277.

Recrystallization of theophylline was carried out from an ethanol:methylene chloride solution, using carbon dioxide as antisolvent. The two variants of the technique - bubbling CO2 (GAS) or spraying the solution (SAS) - were investigated in order to explore the effect of specific conditions on physical (particle size distribution) and chemical (crystalline form) attributes of the product. The particle size analysis showed that particles were almost insensitive to the operating conditions in the GAS mode. The analysis of phase behavior revealed that precipitation occurred for a CO2 mole fraction above 0.63 and when the CO2-solvent system crossed the L-V coexistence line, i.e. when the bi-phasic mixture merged as a single phase. In the SAS mode, the vicinity of the mixture critical point allowed for reducing the mean size and the size distribution as well. Most X-ray diffraction patterns of CO2-processed powders were found to exhibit new peaks, with an occurrence influenced by process version, pressure and temperature. The comparison with theoretical patterns obtained through various crystal modifications indicated that the new patterns were attributable to a change of the symmetry group rather to a textural effect. Finally, SAS mode was proven to be more efficient at producing narrower and smaller particle size than GAS especially when co-flow injectors were used.

« Phenomenological study of the densification behavior of Aluminum-Nickel powder mixtures during cold isostatic pressing and differential hydrostatic extrusion.»

M. Andasmas, P. Langlois, N. Fagnon, Th. Chauveau, A. Hendaoui, D. Vrel

Powder Technology, 207, 1-3, 304-310.

Compaction and extrusion of Al and Ni powder mixtures were performed by Cold Isostatic Pressing (CIP) and Differential Hydrostatic Extrusion (DHE) at room temperature. Relative density and Vickers hardness were determined as a function of the compaction pressure, showing a significant increase in the density with increasing Al content for comparable pressing conditions; at the same time, the addition of a very small quantity of Al in Ni decreases the hardness significantly. Williamson–Hall method was applied to determine microstrains evolution during CIP, and X-Ray Diffraction (XRD) analyses were performed to investigate texture evolution during DHE. Finally Archimedes’ principle was used to estimate the densification occurring during DHE.

2010

« Synthesis of high-purity polycrystalline MAX phases in Ti–Al–C system through Mechanically Activated Self-propagating High-temperature Synthesis.»

A. Hendaoui, D. Vrel, A. Amara, P. Langlois, M. Andasmas, M. Guerioune

Journal of the European Ceramic Society, 2010, 30, 1049-1057.

Ternary MAX phase compounds were synthesized using an alternative route called MASHS (Mechanically Activated Self-propagating High-temperature Synthesis). This original process combines a short duration ball milling (MA) of reactants (Ti, Al, C) with a self-sustaining combustion (SHS). The particle size evolution of the powder mixture during Mechanical Activation was monitored using XRD profile analysis. The effect of Al-excess was also discussed. XRD and SEM analyses have proved that the activation of the reaction kinetics must be accompanied by a decrease in the overall exothermicity in order to synthesize pure Ti–Al–C MAX phases by MASHS.

« The role of sintering additives on synthesis of cermets by auto-combustion.»

Mahieddine Ali-Rachedi, Wisseme Ramdane, Dominique Vrel, Abdelaziz Benaldjia, Patrick Langlois, Mohamed Guerioune

Powder Technology, 2010, 197, 3, 303-308.

The purpose of this work is to decrease or eliminate porosities in SHS products with sintering additives. The Ti–C system has been synthesized for its advantages for refractory, abrasive and structural applications.We attempted to densify TiC by using Nickel addition; this metal is introduced through a secondary reaction 3NiO+2Al. This mixture reacts exothermically and the heat is released according to 3NiO+2Al → Al2O3+3Ni. So, the introduction of the Al2O3 diluent with the starting reactants is necessary because of the explosive character of the thermite reaction. Thus, doping method is finally used to fabricate materials by SHS method (self-propagating high temperature synthesis). Final products were analysed by X-ray diffraction and scanning electron microscopy.

2009

« A novel method for synthesis of low-cost Ti-Al-C-based cermets .»

A. Hendaoui, D. Vrel, A. Amara, P. Langlois, M. Guérioune.

International Journal of Self-propagating High-temperature Synthesis, 2009, 18 :4, 267-272.

Ti2AlC-Ti3AlC2/Al2O3 samples have been successfully synthesized by aluminothermic reduction of TiO2 in the presence of C. Phase composition of resultant products obtained at different Al excess was characterized by XRD. Microstructures of the samples were observed by SEM. XRD analysis proved that it is possible to improve the yield of MAX phases using Al excess. With increasing Al excess, a major MAX phase was found to change from Ti2AlC to Ti3AlC2. .

« Combustion Synthesis of PrBa2Cu3O7-d and YBa2Cu3O7-d Cuprate Materials.»

N. Sehab, A. Harat, A. Benaldjia, A. Amara, M. Guerioune, G. Fillion, D. Vrel, and P. Langlois.

International Journal of Self-propagating High-temperature Synthesis.

PrBaCuO and YBaCuO cuprate materials were prepared from cooper, barium peroxide, and yttrium/praseodymium oxide by SHS and standard solid-state synthesis. SHS reactions were carried out using relatively large cooper particles (< 63 im) to obtain small product samples (13 mm in diameter). High ambient temperature was used to stabilize a combustion front in the ignited pellets. Explored was the effect of cooper particles size, starting density, and ambient temperature on phase evolutions in synthesized materials. .

« One step synthesis and densification of Ti-Al-C MAX phases-based cermets by ETEPC.»

A. Hendaoui, D. Vrel, A. Amara, N. Fagnon, P. Langlois, M. Guérioune.

International Journal of Self-propagating High-temperature Synthesis, 2009, 18 :4, 263-266.

The Electro-Thermal Explosion under Pressure with Confinement (ETEPC) mode of SHS has been studied for producing possibly low-porosity Ti2AlC and Ti3AlC2 from elemental powders in a very short processing time. The effect of maintaining the electric current after the ignition of exothermic reaction has also been studied. A better achievement of the desired reaction, with a total yield of MAX phases up to 73%, was obtained with maintaining the electric current for 4 s after ignition of the exothermic reaction in the Ti: Al: C = 2:1:1 composition. XRD studies revealed also composition gradients. .

« Extrusion-Activated Thermal Explosion Applied to Intermetallics Processing.»

Mohamed Andasmas, Dominique Vrel, Nicolas Fagnon, Thierry Chauveau, Ali Hendaoui, Patrick Langlois,

High Pressure Research, 29, 4, 625-629 (2009).

The present study deals with synthesizing the NiAl compound through the thermal-explosion route akin to self-propagating high-temperature synthesis under the novel circumstance of extrusion-induced mechanical activation. Either route has the potential for addressing the intermetallics processing cost problem and both reactions may alike be significantly enhanced by prior activation. Reactant powders were homogeneously mixed and precompacted by cold isostatic pressing (CIP) at 800 MPa. Hydrostatic extrusion was performed with a lower-chamber pressure fixed at 50 MPa and an upper-chamber pressure of 1.4 GPa, hence yielding a fully dense Ni+Al mixture, maximizing the contact areas between reactants and enhancing the specific surfaces of Al without such a grain refinement as with mechanical activation by ball milling. After heating up to 550 °C with a rate of 10 °C/min, uniquely CIPed samples did not react, whereas those subsequently extruded did react in the thermal-explosion mode with temperature overstepping 1084°C.

« Hot Forging of MAX Compounds SHS-produced in the Ti-Al-C System.»

A. M. Stolin, D. Vrel, S.N. Galyshev, A. Hendaoui, P.M. Bazhin and A.E. Sytchev

International Journal of Self-Propagating High-Temperature Synthesis, 18 (3), 194-199, 2009.

Investigated was the forgeability (extent of compression) of still hot SHS products (MAX phases) formed in the Ti–Al–C system at relatively low applied pressures (1.5–15.0 MPa in a press punch) in conditions of free SHS compression. The extent of compression was measured as a function of time delay (between the end of reaction and compression) and applied pressure. Characterized were the microstructure and phase composition of thus obtained MAX compounds.

2007

« Habilitation à Diriger les Recherches - Mémoire de travaux. Contribution à l'Etude du Procédé de Synthèse de Matériaux par Combustion Solide (SHS).»

Dominique Vrel

« Main Recent Contributions to SHS from France.»

J.-C. Niepce et al.

International Journal of Self-Propagating High-Temperature Synthesis, 16 (4) 235-255, 2007.

Both in situ TRXRD and IR thermography, on the one hand, and different levels of modeling, on the other, have generated a strong progress in the knowledge and control of numerous SHS reactions. The SHS of simple binary materials, such as intermetallics (FeAl, MoSi2, NbAl3, etc.), oxides (e.g. ZrO2), carbides (e.g. SiC) or nitrides, more complex materials, such as mullite, SiAlONs, MAX phases, composites (SiO2–Al2O3, NiAl–ZrO2), powders in their more complicated states, such as well controlled microstructures, fully densified intermetallics, smart composites, and hard coatings carried out by GFA researchers greatly contributed to the worldwide competition to harness the potential of SHS. On the occasion of the 40th anniversary of SHS, this paper is giving an overview of the main results obtained by GFA over the last ten years.

« Structural characterization and superconducting properties of MgB2 prepared by SHS method.»

W. Ramdane, B. Bendjemil, A. Hafs, A. Hendaoui, M. Guérioune, D. Vrel

International Journal of Self-Propagating High-Temperature Synthesis, 16 (4), 207-212, 2007.

Self-propagating high-temperature synthesis (SHS) of bulk MgB2 superconductor from Mg-2B powder blend is reported. This reaction proceeds violently at 100 A under a protective atmosphere. Since the heat of reaction of Mg and B was not enough for chain reaction, then (Ti + C) mixed powders were used as the ignition agent to assist the reaction (Mg + 2B). In this case, the combustion front moved without any difficulty. The diffraction lines of the product can be indexed to a hexagonal MgB2phase, with lattice constants a = 3.0845 Å, and c = 3.5259 Å. For comparison, the direct synthesis of (Mg + 2B) mixture was carried out at (800°C–1000°C). It can be found, that high-temperature sintering (1000°C) will induce the formation of impurities. The MgB2grains are fine, well compacted and more homogenous. The structure of materials was studied using XRD, FESEM and EDX. M-H curvatures were measured under the magnetic fields between –80 kOe and 80 kOe. Jcwas calculated from width of magnetization hysteresis loops based on the extended Bean Model.

« Quasicrystalline Al70Cu20Fe10 by thermal explosion Effect of AlCu doping on magnetic properties.»

B. Bendjemil, J. Bougdira, N. Segheri, W. Ramdane, A. Hafs, S. Habes, D. Vrel

International Journal of Self-Propagating High-Temperature Synthesis, 16 (4), 225-230, 2007.

Polycrystalline quasi-crystals of icosahedral Al70Cu20Fe10(i-Al70Cu20Fe10) were prepared by thermal explosion (TE) of mechanically activated mixture of Al, Cu, Fe powders doped with AlCu. The effect of AlCu dopant was studied by XRD, field emission scanning electron (FESEM), optical microscopy (OM), atomic emission spectroscopy (AES), and energy-dispersive X-ray microanalysis (EDX). The synthesized i-Al70Cu20Fe10 and intermetallics (Al3Fe, Al2Cu) show soft ferromagnetic and paramagnetic properties, respectively.

« SHS quenching as a route to bulk glassy Fe34Co34B10Si14Nb8 alloys.»

B. Bendjemil, N. Segheri, W. Ramdane, A. Hafs, D. Vrel

International Journal of Self-Propagating High-Temperature Synthesis, 16 (4), 231-234, 2007.

The method of SHS quenching combined with dynamic annealing was used to prepare bulk amorphous metallic glass alloys Fe34Co34B10Si14Nb8 in a two-stage process. The structural properties and microstructure of thus prepared materials were found to be close to those produced by other methods, such as melting-injection-molding and melt spinning.

« Reaction mechanism of MoSi2 produced by SHS from Mechanically-Activated powder mixture.»

G.Cabouro, S. Chevalier, E.Gaffet, A.S.Rogachev, D.Vrel, N. Boudet, F.Bernard

International Journal of Self-Propagating High-Temperature Synthesis, 16 (2), pp. 79-86 (June 2007)

Controlling the Mechanically Activated Self-propagating High-temperature Synthesis (MASHS) process is exceedingly important for production of MoSi2-based materials with a desired microstructure. Consequently, it seemed essential to carry out Time-Resolved X-ray Diffraction (TRXRD) experiments using an X-ray synchrotron beam (DM2, ESRF Grenoble) coupled with IR thermographic measurements to monitor in situ the structural and thermal evolutions taking place during SHS. The versatility of this technique and new possibilities offered by the design of new sample holders have already been proved. In addition, this work clearly shows that this equipment is perfectly adapted to investigating phase transitions occurring during the MASHS process in the Mo-Si system.

« SHS Reactions in the NiO-Al System: Influence of the Stoichiometry.»

D. Vrel, A. Hendaoui, P. Langlois, S. Dubois, Véronique Gauthier, Benoit Cochepin

International Journal of Self-Propagating High-Temperature Synthesis, 16 (2), pp. 62-69 (June 2007)

Thermite reactions in the NiO-Al system have been studied. In addition to the case when the stoichiometry is set up to produce metallic nickel and alumina, we studied the case when Al is added in excess in order to react with the Ni produced through the reduction of nickel monoxide with Al to produce various nickel aluminides. As thermite reactions are highly exothermic, in order to provide a better understanding of the reactions, alumina has been added to the green mixture to reduce the reaction rate and overall exothermicity, in amounts corresponding up to 50% of the overall heat capacity of the sample.

« Investigation of the SHS mechanisms of titanium nitride formation by in-situ time-resolved diffraction and infrared thermography.»

D. Carole, N. Frety, S. Paris, D. Vrel, F. Bernard, R.-M. Marin-Ayral

Journal of Alloys and Compounds, 436 (1-2), pp. 181-186, 2007.

The self-propagating high-temperature synthesis (SHS) or combustion synthesis is a promising process to produce advanced ceramics due to the high purity of the elaborated materials and the very short synthesis time. Titanium nitride has been synthesised from pressed titanium powder and a nitrogen gas flow under a 0.1 MPa pressure. The influence of the addition of a TiN diluent was investigated. For the first time, SHS reaction mechanisms were determined from in situ time-resolved X-ray diffraction (TRXRD) experiments using the synchrotron radiation. These experiments were coupled with infrared thermography to study the propagation of the combustion reaction. It appeared that the initiation of the combustion reaction is due to the α-Ti to β-Ti phase transformation. A single δ-TiN phase was then produced from pressed titanium powder. The addition of a TiN diluent resulted in the synthesis of a multiphase material with the presence of the α-Ti, Ti2N and TiN phases. The combustion reaction propagates in a surface mode at a velocity ranging from 6.4 to 7.4 mm/s.

« Crystal growth of TiC grains during SHS reactions.»

B. Cochepin, V. Gauthier, D.Vrel, S. Dubois

Journal of Crystal Growth 304 (2), pp. 481-486.

The microstructure formation of TiC during self-propagating high-temperature synthesis (SHS) reactions is investigated thanks to the quenching method. The morphology and chemical composition of titanium carbide grains are characterized, during the growth phase, from X-ray diffraction (XRD), scanning electron microscopy (SEM) and wavelength dispersion spectroscopy (WDS) analyses. It is demonstrated that TiCx grains nucleate with a great deficit in carbon; the carbon composition evolves towards the stoichiometry during the growth phase. The TiC grain sizes are then coupled to thermal data acquired by infra red (IR) thermography. It is shown that the convolution of the temperature and of the time elapsed in the temperature range Tmax≈ 1000 K constitute a pertinent parameter to give account of the variation of TiC grain sizes.

« In situ synchrotron investigation of MoSi2 formation mechanisms during a current activated SHS-sintering.»

G. Cabouro, S. Chevalier, E. Gaffet, D. Vrel, N. Boudet, F. Bernard

Acta Materialia 55 (18), pp. 6051-6063.

The development and control of the mechanically activated spark plasma sintering (MASPS) process is the main objective to be achieved in producing bulk nano-organized materials with perfectly controlled composition and microstructure. Consequently, it was essential to develop original experiments, such as time resolved X-ray diffraction with the X-ray synchrotron beam (D2AM-BM2, ESRF Grenoble) coupled to IR thermography to monitor in situ structural and thermal evolution during the current-activated SHS sintering process in the Mo–Si system. A new sample holder was designed in order to reproduce the synthesis conditions of the MASPS process, obviously without the consolidation step. The versatility of the set-up and the new possibilities offered by the design of new sample holders allow a new interpretation of MoSi2 formation mechanisms during current-activated SHS sintering.

« Solvent effect on tolbutamide crystallization induced by compressed CO2 as antisolvent.»

P. Subra-Paternault, C. Roy, D. Vrel, A. Vega-Gonzalez, C. Domingo,

Journal of Crystal Growth 309 (1), pp. 76-85.

The aim of this work is to investigate the crystallization of tolbutamide induced by the addition of compressed carbon dioxide, with a particular focus on the role of the liquor solvent on the product characteristics. Crystals morphology and sizes were documented by microscopy and laser diffraction, respectively; since tolbutamide exists in four polymorph forms, characterizations by powder X-rays diffraction, differential scanning calorimetry and Raman spectroscopy were carried out. When processed from acetone or ethyl acetate, the drug crystallizes as polyedres and in a crystal lattice typical of Form III. If ethanol is added to acetone, Form I appears in the powder and becomes predominant for a content of 29% (in mol) and above; at the same time, mean particles size decreases. However, ethanol improves the solubilization of tolbutamide in the formed CO2–solvent mixture, and is thus not favourable to a good yield of production. Mixtures of acetone with poor solvents such as diethyl ether and water were tested out; both enable the recovery of a mixture of Forms I and III, but with no significant improvement in sizes or yields compared with pure acetone or acetone–ethanol mixtures. Finally, the comparison with crystals obtained by evaporation indicates that the solvent itself was the main cause of the crystal phase observed, rather than the supercritical treatment.

« Microstructural study of titanium carbonitride by combustion synthesis.»

D. Carole, N. Frety, S. Paris, D. Vrel, F. Bernard, R.-M. Marin-Ayral

Ceramics International, 33 (8), pp 1525-1534.

The self-propagating high-temperature synthesis (S.H.S.) process, which is promising for the fabrication of ceramic materials, was chosen to elaborate titanium carbonitride materials. The influence of parameters such as nitrogen gas pressure and carbon ratio on the microstructure was studied. A single phase product of Ti(C,N) is obtained for a carbon ratio under 15 at.% and a nitrogen pressure of 36 MPa. The increase of the carbon ratio corresponds to a decrease of the maximum temperature reached during the synthesis. Time resolved X-ray diffraction measurements (TRXRD) with the synchrotron radiation were used to determine the reaction mechanisms. We could observe that the synthesis of Ti(C,N) is preceded by the formation of titanium nitride. This reaction is initiated by the allotropic transition of α-Ti phase into β-Ti. In the final material the presence of sub-stoichiometric phases such as Ti2N and α-Ti was observed.

« Time resolved X-Ray diffraction study of NiAl and NiAl-ZrO2 composites processed by SHS.»

D. Tingaud, L. Stuppfler, S. Paris, D. Vrel, F. Bernard, C. Penot, F. Nardou

International Journal of Self-Propagating High-Temperature Synthesis, 16 (1), 12-17 (mars 2007)

NiAl and NiAl-ZrO2 intermetallic composites were prepared from pressed elemental powders by SHS in a dynamic vacuum. The effect of diluent properties (such as conductivity and grain size) on the parameters of the SHS reaction has been investigated by time-resolved X-ray diffraction (TRXRD). By decreasing the reactivity of the green mixture, these nonreactive additives not only slow down the velocity of combustion front propagation but can also give rise to local melting of the product. Synchrotron radiation was also used to elucidate the reaction mechanism. It has been found that the combustion synthesis of NiAl is triggered by aluminum melting and proceeds via the formation of two transient intermetallic phases, NiAl3 and Ni2Al3. In the final product, only the NiAl phase has been detected.